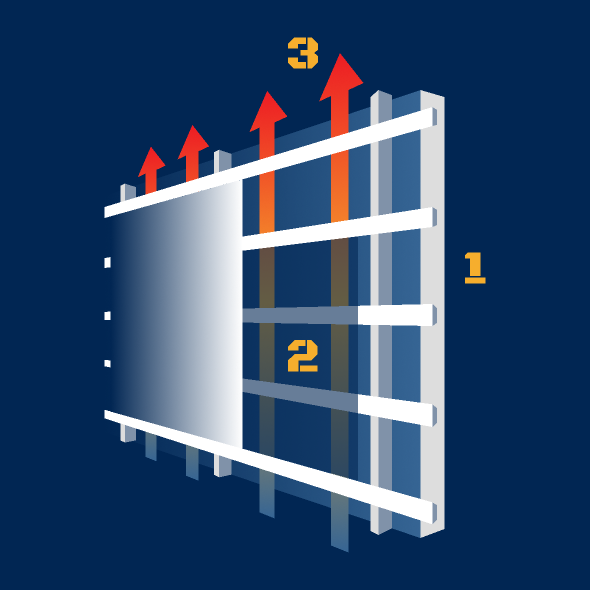

Ventilated facades are optimal building envelopes, both aesthetically and physically. Ventilated facades consist of multiple layers. The first outer layer consists of panels made from facade cladding materials, such as aluminium sheets, aluminium composite panels (ALUCOBOND), fibre cement panels, etc.

The visible outer layer is composed of facade panels suspended by (cassetted) or glued to the metal substructure.

The penultimate layer, between the metal substructure and mineral wool, is a ventilated cavity in which air can circulate freely. This cavity is the specific feature of ventilated facades.

The last layer is composed of fleece laminated mineral wool (covered by a diffusive membrane) that is affixed to the building wall.

1. Water molecules diffuse from the interior to the exterior of the facade through the walls.

2. Vapour easily passes through mineral wool to the ventilated cavity due to the wool’s fibrous structure and vapour permeable, but watertight, membrane.

3. The vapour is then eliminated from the facade by air.

The majority of physical properties are ensured by internal layers of the facade, those that are hidden from view. A huge advantage of ventilated facades is the fact that the facade cladding can assume almost any shape: undulating, rounded, sharp, regular and irregular geometry. From an aesthetic point of view, even the most complicated and demanding building facades can be executed by ventilated facades.

As a comparative advantage in the choice of a potential contractor, in addition to the large and well-known capacities for aluminium systems, we would like to point out the aluminium composite panel ventilated facade program, for which we own one of the most advanced production and processing lines in Croatia. CNC processing machine for sheet cutting, profiling and drilling, punching and perforating machine, and a machine for processing plate rims.